Measurement Services

Surface mechanical material testing for you

The development and optimization of protective coatings requires reliable measurement data. Also for coatings with other primary purposes the mechanical stability becomes more and more important to guarantee their durability.

Numerical modeling can only be as good as the input parameters. Accurate data for Young’s modulus or yield strength of coatings are required for calculations. However, for thin coatings reliable data are difficult to obtain. ASMEC can determine these data for you.

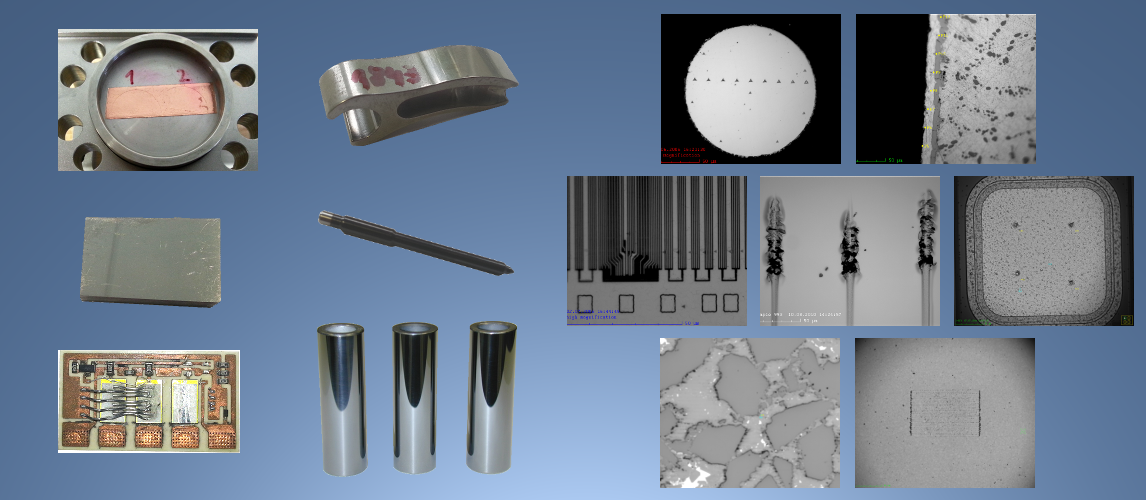

You can benefit from the longtime know how and experience of our stuff for the mechanical characterization of coatings and surfaces. We offer measurement services for a multitude of test methods:

- Depth dependent hardness and modulus measurements

- Determination of hardness profiles at cross sections (minimum film thickness 5 µm)

- E−Modulus measurements at ultra-thin hard and smooth coatings with thicknesses between 10 nm − 500 nm.

- Micro scratch tests for the measurement of yield strength and for the comparison of adhesion properties

- Micro wear tests

- Mapping of mechanical properties (hardness, modulus, contact stiffness, phase shift, friction, contact resistance) and of the surface topography

- Special tests according to agreements

ASMEC offers as a service the determination of the tip area or radius function. The good agreement of the area functions of calibrated reference tips with our test methods and software was already 2001 confirmed in a comparison with the Physikalisch-Technische Bundesanstalt:

[ T. Chudoba, K. Herrmann, Verfahren zur Ermittlung der realen Spitzenform von VICKERS− und BERKOVICH−Eindringkörpern, Härtereitechnische Mitteilungen, HTM 56 Heft. 4 (2001) 258 ]