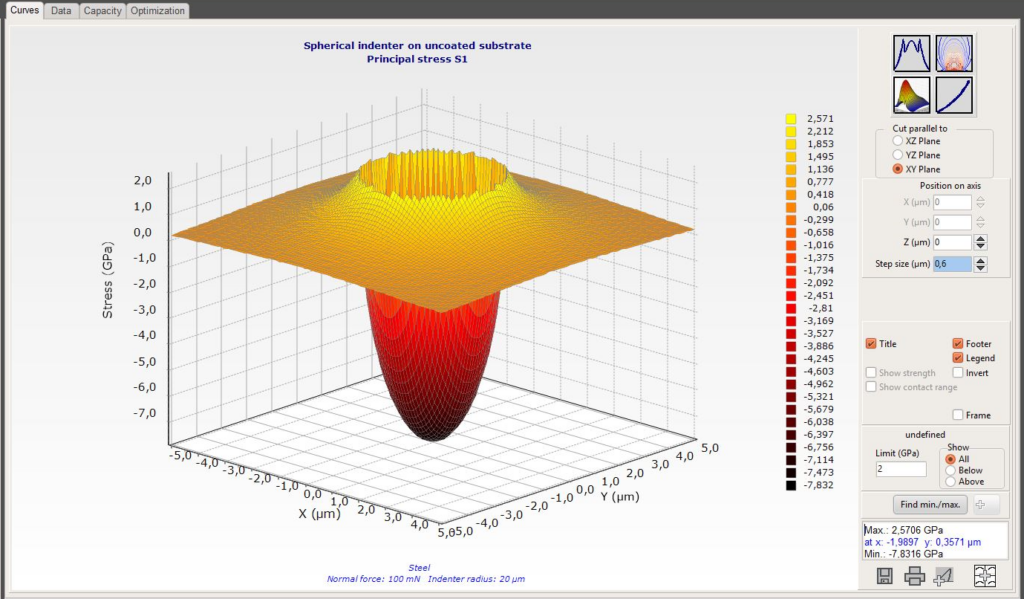

Elastica: Kontaktmechanische Berechnungen schnell und präzise.

InspectorX: umfassende Auswertungsmöglichkeiten für Eindruckmessungen

Wir entwickeln neue Methoden, Software und Messtechnik zur mechanischen Charakterisierung von Oberflächen für Sie. Für mehr Informationen kontaktieren sie uns gerne.

Wir ermitteln Messwerte für eine Vielzahl von Testmethoden für sie, mithilfe unseres eigenen Gerätebestands.

Wir führen den Service für die erste Generation von Nanomechanischen Testern mit der Bezeichnung UNAT durch.

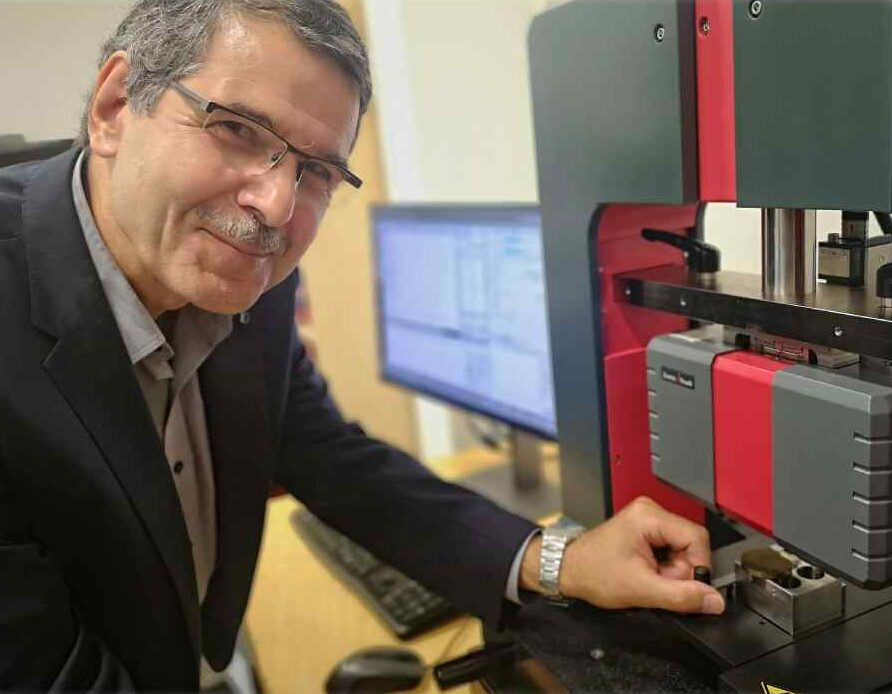

Die ASMEC Advanced Surface Mechanics GmbH wurde im Dezember 2003 von Dr. Thomas Chudoba, einem anerkannten Experten auf dem Gebiet der Oberflächenmechanik und Nanoindentation, gegründet. Ziel der Gründung war die Entwicklung von fortgeschrittener Messtechnik, Methoden und Software zur mechanischen Charakterisierung und Optimierung von Oberflächen und Schichten. Dies ist auch heute noch unser Anspruch..

Advanced

Surface

Mechanics GMBH

Maria-Reiche-Str. 1

01109 Dresden

Deutschland